I-PI (polymide) i-powder, induku, ishidi, imikhiqizo ye-CNC design

I-Thermosetting polyamides yaziwa ngokuqina okushisayo, ukumelana okuhle kwamakhemikhali, izakhiwo ezinhle kakhulu zemishini, kanye nombala we-orange orange / ophuzi. Ama-polyamides ahlanganiswe ngama-graphite noma ama-fiber fiber aqiniswe amandla afinyelela ku-340 MPA (49,000 psi) kanye ne-fledral moduli ka-21,000 MPA (3,000,000 PSI). I-Thermoses polymer matrix polyamides ekhombisa ama-creep aphansi kakhulu namandla aphezulu aphezulu. Lezi zakhiwo zigcinwa ngesikhathi sokusetshenziswa okuqhubekayo kumazinga okushisa afinyelela ku-232 ° C (450 ° F) kanye nohambo olufushane, olungama-704 ° C (11] Izingxenye ezibunjiwe ze-polymide nama-laminates zinokumelana nokushisa okuhle kakhulu. Amazinga okushisa ajwayelekile azosebenza ezingxenyeni ezinjalo kanye nama-laminates aqala kusuka ku-cryogenic kuya kulabo abangaphezulu kuka-260 ° C (500 ° F). Ama-polyamides nawo amelana nemvelo ukuhlanganiswa kwamalangabi futhi akuvamisile ukuhlanganiswa nokubuyiselwa kwamalangabi. Iningi liphatha isilinganiso se-VTM-0. I-Polymide Lamimenien ine-Flueral At Sernt Half Life ngo-249 ° C (480 ° F) amahora angama-400.

Izingxenye ezijwayelekile ze-polzimide azithintwa yi-solvents evame ukusetshenziswa namafutha - kufaka phakathi ama-hydrocarbons, ama-esters, izifebe, ama-Fern kanye ne-ferns. Baphinde bamelane nama-acid abuthakathaka kepha abanconywa ukuthi basebenzise izindawo eziqukethe ama-alkali noma ama-inorganic acid. Amanye ama-polyamides, anjenge-CP1 kanye neCorin XLS, asolvent-ancibilika futhi abonise ukucaca okuphezulu. Izakhiwo ze-solubity zibaboleka ekufafeni kanye nezicelo zokushisa okushisa okuphansi.

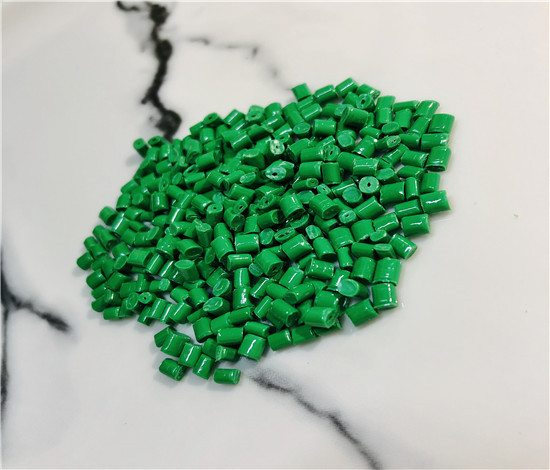

Izici ze-PI

I-PI iyi-polymer yayo ye-flame retarmer yayo, engashisi ekushiseni okuphezulu

Izakhiwo zemishini ukuzwela okuphansi kokushisa

Okuqukethwe kunekhono elihle kakhulu lokufaka imibala, kungafinyelela izidingo ezahlukahlukene zokufanisa kombala

Ukusebenza okuhle kakhulu okushisayo: izinga lokushisa eliphakeme kanye nokumelana okuphansi kokushisa

Ukusebenza kukagesi okuvelele: Ukufakwa kukagesi okuphezulu

Inkambu yesicelo esikhulu se-PI

Kusetshenziswe kalula emishini, ithuluzi, izingxenye zezimoto, ugesi kanye ne-elekthronikhi, ujantshi, izinto zasekhaya, ezempi, amapangi e-Textile, amathangi e-Fuel, amathangi e-Fuel kanye nemikhiqizo ye-Fuel Engineerising.

Izinto ze-polymide zingasindi, zivumelana nezimo, zimelana nokushisa namakhemikhali. Ngakho-ke, zisetshenziswa embonini ye-elekthronikhi yezintambo eziguqukayo kanye nefilimu efaka ukufakwa ku-Magnet Wire. Isibonelo, kwikhompyutha ye-laptop, ikhebula elixhumanisa ibhodi eliphambili le-logic kwisibonisi (okufumanekile ngaso sonke isikhathi lapho i-laptop ivuliwe noma ivaliwe) imvamisa iyisisekelo se-polymide nabaqhubisi bethusi. Izibonelo zamafilimu we-polymide zifaka i-apical, kapton, i-lileilex, i-vtec PI, uNorton th neKapTrex.

Ukusetshenziswa okwengeziwe kwe-polymide resin kunjengeserser yokufakelwa kanye nokuhamba ekwenziweni kwemibukela ehlanganisiwe nama-mems chip. Izendlalelo ze-polymide zinezinkinga ezinhle zemishini kanye namandla asheshayo, okusiza nokunamathela phakathi kwezendlalelo ze-polymide noma phakathi kwesendlalelo se-polymide kanye nesendlalelo sensimbi.

| Idlelo | Amacala okufaka isicelo |

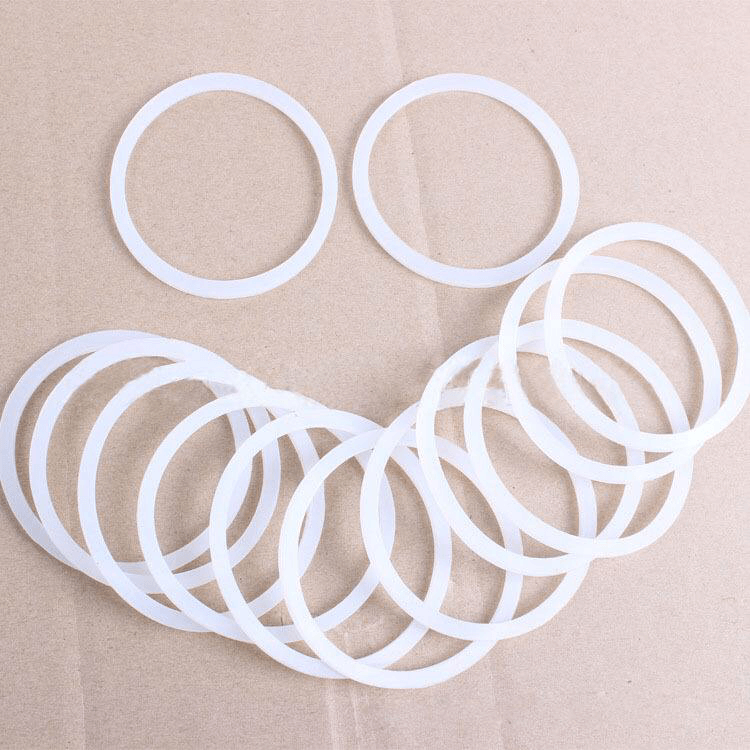

| Ingxenye Yezimboni | Ukuzithathela okushisa okuphezulu okuphezulu, i-compressor piston riston, isivalo sendandatho |

| Izesekeli zikagesi | Ama-radiator, fan ukupholisa, isibambo somnyango, i-Fuel Tank cap, i-air yokuntrake grille, ikhava yamathangi amanzi, umnikazi wekhambi |

Amamaki we-Spla-3D nencazelo

| Khuphuka | Ukufanisa |

| Spla-3D101 | Pla asebenza kakhulu. Pla account ngaphezulu kwama-90%. Ukuphrinta okuhle kwe-anhigh amandla. Izinzuzo zizinzile zakha, ukuphrinta okubushelelezi kanye nezinto ezihle kakhulu. |

| Spla-3DC102 | Pla account account ngo-50-70% futhi agcwaliswa kakhulu futhi acutshungulwe. Izinzuzo ezivumayo ezakha, ziphrinte okubushelelezi zokuphrinta i-andexcellent mechanical Properties. |