Inqubo yokukhiqiza yezinhlayiya zepulasitiki eziguquliwe ikakhulukazi ifaka: inqubo yokuxuba, inqubo yokukhishwa, ukupakishwa.

1. Izivivinyo eziyisithupha zokuxuba: ukukhokhisa, ukwamukela, ukuhlanza, ukuhlukanisa, ukujikisa, ukuxuba.

2

I-3. Ukwabelana ngezinto ezibonakalayo: Qinisekisa ukuthi izinto ezifanele zokuvumba ngeke zibe ngephutha ekusebenzeni.

4. Ukuxuba: I-oda lokuxuba okujwayelekile yile: I-Particle Powder, Toner.

Ⅱ. Ukondla.

Ngokulawula ikhompyutha, ukukhala kulawulwa ngokuya ngoshintsho lwesisindo.

Izinzuzo:

1. Qinisekisa ukunemba kwezinto ezibonakalayo.

2. Yehlisa ukucekelwa phansi kwezinto zokwakha.

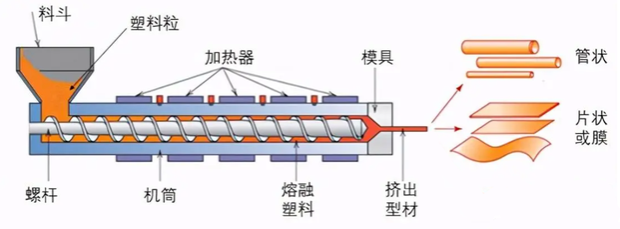

Ⅲ. Isikulufa sepulasitiki, ukukhishwa, ukudweba.

Ⅲ. Isikulufa sepulasitiki, ukukhishwa, ukudweba.

Ⅳ. Ukupholisa kwamanzi (ukucwila).

Ipholile futhi ipholile umucu wepulasitiki odluliselwe ku-extruder.

Ⅴ. Ukomisa umoya (iphampu yamanzi, ummese womoya).

Susa umswakama osuka emgqeni wepulasitiki bese uyomisa.

Ⅵ. Ukuwohloka.

Ngokuvamile, usayizi wezinhlayiya ezisikiwe yi-3mm * 3mm PVC Material Standard: GB / T8815-2002.

Ⅶ. I-TIFTING (Screen Screen).

Hlunga izinhlayiya ezisikiwe futhi ulawule usayizi wezinhlayiya.

Ⅷ. Ngaphezulu kwe-overmagnetization (isihlungi se-magnetic).

Suck izinhlayiya ezinokungcola kwensimbi.

Ⅸ. Ukuhlolwa kwesayithi.

Kungumsebenzi wokubona ukubukeka ikakhulukazi, okuthola ukuthi umbala wezinhlayiya ukhuphuke ngokwezinga nokuthi uyabumbene.

Ⅹ. Ukuxuba (okuphindwe kabili kwe-roe rotary mixer).

Qinisekisa ukuthi umbala kanye nokusebenza kwezinhlayiya zepulasitiki eziguquliwe kufana.

Ⅺ. Ukupakisha (wonke umshini wokupakisha we-elekthronikhi).

Ⅻ. Ukubeka

Isikhathi Seposi: 23-12-22