Izinga lokushisa lesikhunta libhekisela ekushiseni okungaphezulu kwesikhunta esihlangana nomkhiqizo ohlelweni lokubumba umjovo. Ngoba kuthinta ngokuqondile izinga lokupholisa lomkhiqizo emgodini wesikhunta, okunomthelela omkhulu ekusebenzeni kwangaphakathi kanye nekhwalithi yokubukeka komkhiqizo.

1. Umphumela wokushisa kwesikhunta ekubukeni kwemikhiqizo.

Izinga lokushisa eliphakeme lingathuthukisa ukugcwala kwe-resin, ngokuvamile okwenza ingaphezulu lomkhiqizo libushelelezi futhi licwebezele, ikakhulukazi ukuthuthukisa ubuhle obungaphezulu bemikhiqizo ye-resin eqinisiwe ye-fiber fiber. Ngesikhathi esifanayo, iphinde ithuthukise amandla nokubukeka komugqa we-fusion.

Ngokuqondene nendawo eqoshiwe, uma izinga lokushisa lesikhunta liphansi, kunzima ukuthi ukuncibilika kugcwalise impande yokuthungwa, okwenza ubuso bomkhiqizo bubonakale bucwebezela, futhi "ukudlulisa" akukwazi ukufinyelela ukuthungwa kwangempela kwendawo yokubumba. . Umthelela okahle wokukhipha ingatholakala ngokwandisa izinga lokushisa lesikhunta kanye nezinga lokushisa lempahla.

2. Ithonya ekucindezelekeni kwangaphakathi komkhiqizo.

Ukwakheka kokwenza ukucindezeleka kwangaphakathi kubangelwa ngokuyisisekelo ukuncipha okushisayo okuhlukile ngesikhathi sokupholisa. Lapho umkhiqizo wakhiwe, ukupholisa kwawo kudlulela kancane kancane ukusuka phezulu kuya ngaphakathi, futhi indawo yokuqala iyancipha futhi iqine, bese kancane kancane ingena ngaphakathi. Kule nqubo, ukucindezeleka kwangaphakathi kukhiqizwa ngenxa yokuhluka kwejubane lokunciphisa.

Lapho ukucindezeleka kwangaphakathi okusele engxenyeni yepulasitiki kuphakeme kunomkhawulo wokunwebeka we-resin, noma ngaphansi kokuguguleka kwemvelo ethile yamakhemikhali, kuyokwenzeka imifantu ebusweni bengxenye yepulasitiki. Ucwaningo lwe-PC kanye ne-PMMA resin esobala lubonisa ukuthi ukucindezeleka kwangaphakathi okusalayo kungqimba olungaphezulu kuyacindezelwa futhi isendlalelo sangaphakathi siyandiswa.

Ukucindezeleka okucindezelwayo okungaphezulu kuncike esimweni sokupholisa kwamanzi, futhi isikhunta esibandayo senza inhlaka encibilikisiwe iphole ngokushesha, okwenza imikhiqizo ebunjiwe ikhiqize ukucindezeleka okukhulu okuyinsalela yangaphakathi.

Ukushisa kwesikhunta kuyisimo esiyisisekelo kakhulu sokulawula ukucindezeleka kwangaphakathi. Uma izinga lokushisa lesikhunta lishintshwa kancane, ukucindezeleka kwangaphakathi okusele kuzoshintshwa kakhulu. Ngokuvamile, ukucindezelwa kwangaphakathi okwamukelekayo komkhiqizo ngamunye kanye ne-resin kunomkhawulo wokushisa wesikhunta ophansi kakhulu. Lapho wenza ibanga elincanyana elinezindonga noma ibanga elide lokugeleza, izinga lokushisa lesikhunta kufanele libe phezulu kunobuncane bokubumba okuvamile.

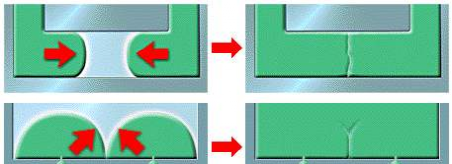

3. Thuthukisa ukungqubuzana komkhiqizo.

Uma ukuklanywa kwesistimu yokupholisa yesikhunta kungenangqondo noma izinga lokushisa lesikhunta lingalawulwa kahle, futhi izingxenye zepulasitiki azipholile ngokwanele, kuzokwenza ukuthi izingxenye zepulasitiki zigoqe.

Ukulawulwa kwezinga lokushisa kwesikhunta, umehluko wokushisa phakathi kwesikhunta esihle kanye nesikhunta esibi, umgogodla wesikhunta nodonga lwesikhunta, udonga lwesikhunta kanye nokufaka kufanele kunqunywe ngokuvumelana nezici zesakhiwo semikhiqizo, ukuze ulawule. izinga lokupholisa lokuncipha kwengxenye ngayinye yokubumba. ngemva kokudilizwa, izingxenye zepulasitiki zivame ukugoba lapho zihamba khona ngezinga lokushisa eliphakeme, ukuze zisuse umehluko wokuncipha wokuma futhi zigweme izingxenye zepulasitiki ezinyakazayo ngokomthetho wokuma. Ezingxenyeni zepulasitiki ezinokwakheka okulinganayo ngokuphelele kanye nesakhiwo, izinga lokushisa lesikhunta kufanele ligcinwe lihambisana ngokufanele, ukuze ukupholisa kwengxenye ngayinye yengxenye yepulasitiki kufanele kulinganiswe.

4. Kuthinta ukuncipha kokubumba komkhiqizo.

Izinga lokushisa eliphansi lesikhunta lisheshisa i-molecular "orientation for freezing" futhi likhuphula ukujiya kongqimba oluqandisiwe lokuncibilika emgodini wesikhunta, kuyilapho izinga lokushisa eliphansi lesikhunta livimbela ukukhula kwekristalu, ngaleyo ndlela kunciphisa ukuncibilika kokubumba kwemikhiqizo. Ngokuphambene nalokho, lapho izinga lokushisa lesikhunta liphezulu, ukuncibilika kuphola kancane, isikhathi sokuphumula side, izinga lokuma liphansi, futhi kunenzuzo ku-crystallization, futhi ukuncipha kwangempela komkhiqizo kukhulu.

5. Kuthinta ukushisa okushisa okuguquguqukayo komkhiqizo.

Ikakhulukazi kumapulasitiki e-crystalline, uma umkhiqizo ubunjwe ezingeni lokushisa eliphansi lesikhunta, i-molecular orientation kanye ne-crystallization iqhwa ngokushesha, futhi uchungechunge lwamangqamuzana luzohlelwa kabusha ngokwengxenye futhi lucwecwe endaweni yokushisa ephakeme noma izimo zokucubungula zesibili, okwenza umkhiqizo uguge. ngaphansi noma ngaphansi kakhulu kunezinga lokushisa lokushintsha kwe-thermal (HDT) lento.

Indlela elungile ukusebenzisa izinga lokushisa elinconywayo lesikhunta eduze nezinga lokushisa le-crystallization ukuze wenze umkhiqizo ucwebezeliswe ngokugcwele esiteji sokubumba umjovo futhi ugweme i-post-crystallization kanye ne-post-shrinkage endaweni yokushisa ephezulu.

Ngamafuphi nje, izinga lokushisa lesikhunta lingelinye lamapharamitha okulawula ayisisekelo enqubweni yokubumba umjovo, futhi liwukucatshangelwa okuyinhloko ekwakhiweni kwesikhunta.

Umthelela wawo ekwakhiweni, ukucubungula kwesibili kanye nokusetshenziswa kokugcina kwemikhiqizo akunakubukelwa phansi.

Isikhathi sokuthumela: 23-12-22